Business improvement is a constant process. Whenever you are eyeing for higher returns on investment and want to achieve your planned goals, then you must consult a business consultant.

They can advise you and help you to make a strategic plan in order to achieve your goals. One way they do this is by applying the 5S at your organisation.

Know more: lean Manufacturing Techniques

Business improvement consultants say that the 5S system involves the use of many tools and organising a messy and cluttered space which can result in mistakes, delays, losses and inefficiency.

To overcome such challenges that you face, the 5S system is one tool that applies the lean ideas of reduced waste and most value.

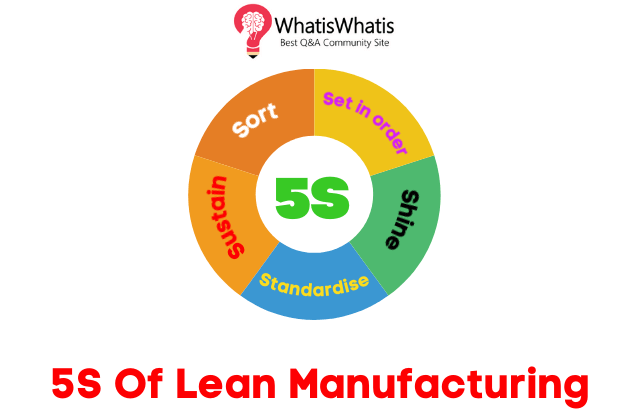

When we are talking about the 5S we sort, set in order, Shine, standardise and sustain operations.

Let’s look at them one by one and see how we can implement it in our daily processes to get the most out of this business methodology.

What are the 5S Of Lean Manufacturing?

1. Sort

You can ask yourself a few questions to define the importance of a certain process or a thing that consumes space and your effort.

It can be a machine, furniture, equipment etc. your work area should be sorted, organised and any unnecessary items should be eliminated.

This goes with the process of production too. Red flagging certain processes that you doubt are necessary can help you to clear out the clutter and streamline the operations.

2. Set in order

Consultancy advise that you should make a logical arrangement of the processes. It would necessarily be important to set everything in order to produce the desired result.

Every production process or every employee should report to its higher manager so that the work could be carried on smoothly.

Know more: lean Manufacturing Training Benefits For The Changing Times

So organising everything and communicating this arrangement to each and every staff member helps you to clear the chaos and confusion that might hinder the processes at your workplace.

3. Shine

Next comes in line Shine. The Shine phase helps in cleaning up the work area. Sweeping, mopping, dusting, all these physical activities can add up to the basic cleaning and the same applies to the maintenance of equipment and machinery.

Planning for maintenance ahead of time helps businesses catch problems and prevent the breakdowns. You can easily instill a sense of responsibility in the staff and help them to stay motivated towards their work.

4. Standardise

When you are continuously checking and monitoring the performance of its process in a production then you are certainly living up to the expectations of lean thinking ideas.

Consultancy Leeds and ISO consultants Yorkshire focuses on standardizing systems and turns the one time efforts into habits. Instruct, schedule and assign regular tasks so that they become a standard operating procedure.

5. Sustain

Businesses must perform the work of these procedures you ask and deploy your managers to oversee the tasks of other employees.

Specifically for each department this helps you to diversify and decentralize your authority while overseeing the whole production from a bird’s eye view.

Also Read: What are the Reasons Your business Lacks Credibility?

When 5S is sustained over time your business will start to produce continuous positive results.

Leave a comment